Supply Chain > HV/LV Electrical > Battery Management System

EV Battery Management System

The Battery Management System (BMS) is the hardware and embedded control system that monitors, protects, and manages an EV (Battery Electric Vehicle) traction battery pack. It measures cell and pack conditions, estimates usable state, enforces safety limits, and coordinates charging and discharging. The BMS is both a battery-supply-chain subsystem (pack-level electronics) and a core HV/LV (High-Voltage / Low-Voltage) electrical control element because it directly governs HV safety behavior.

What the BMS does

- Monitoring: cell voltages, temperatures, pack voltage, pack current, isolation status (where used)

- Estimation: SOC (State of Charge), SOH (State of Health), available power and energy limits

- Protection: over/under-voltage, over/under-temperature, overcurrent, short-circuit detection pathways (architecture dependent)

- Control: contactor control, precharge sequencing, charge/discharge limit enforcement

- Balancing: equalizes cells to maintain usable capacity and reduce drift

- Diagnostics and logging: fault reporting, event logs, service data

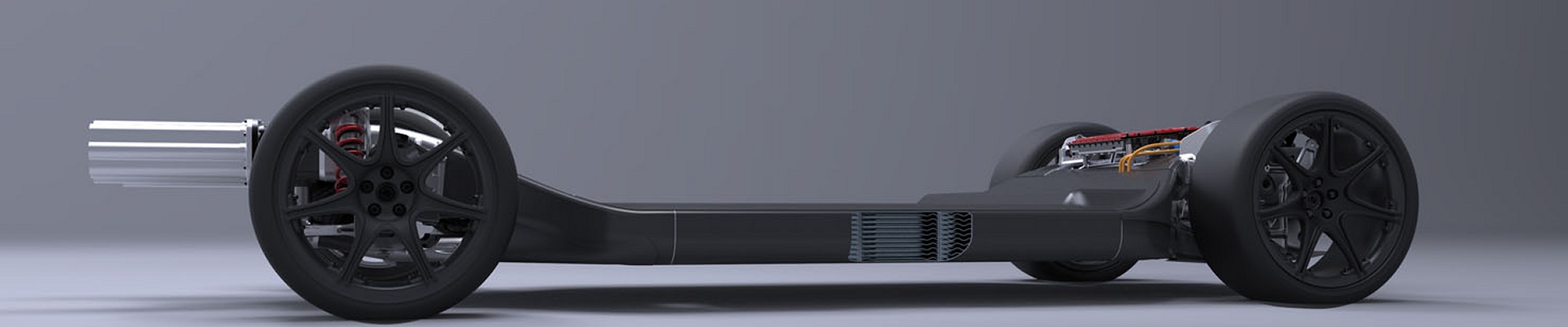

Where the BMS sits in the EV stack

The BMS sits inside or directly adjacent to the battery pack and interfaces with HV distribution, charging systems, thermal management, and the in-vehicle network.

- Physical location: battery pack (common) or pack-adjacent electronics enclosure (varies by design)

- HV interfaces: contactors, precharge, HVIL (High-Voltage Interlock Loop) pathways (architecture dependent), isolation monitoring

- LV interfaces: low-voltage power, communication buses to vehicle controllers

BMS architecture patterns

Most BMS designs fall into a few common topologies.

| Architecture | What it looks like | Typical benefits | Typical tradeoffs |

|---|---|---|---|

| Centralized BMS | One main controller connected to sensing harnesses | Simpler module electronics; fewer distributed boards | More wiring inside pack; scaling complexity with large packs |

| Distributed / modular BMS | Cell monitoring units on modules plus a pack controller | Scales with pack size; shorter sensing runs | More electronics nodes; more internal comms complexity |

| Wireless BMS (where used) | Module sensing units communicate wirelessly to pack controller | Harness reduction; manufacturing simplification potential | Wireless reliability and qualification complexity; design maturity varies |

Core BMS hardware

BMS hardware combines precision sensing with safety-critical control.

| Hardware block | Function | Why it matters |

|---|---|---|

| Pack controller (MCU) | Runs BMS control logic and communications | Safety-critical decision point for pack operation |

| Cell monitoring ICs (AFEs) | Measures cell voltages and temperatures | Measurement accuracy and reliability drive safe limits and usable energy |

| Current sensing | Measures pack current | Required for SOC/SOH estimation and power limiting |

| Voltage sensing | Measures pack voltage and branch voltages | Supports HV safety thresholds and diagnostics |

| Balancing circuits | Balances cell groups | Maintains usable capacity and mitigates drift |

| Isolation monitoring (where used) | Detects leakage to chassis ground | Critical HV safety mechanism; supports fault isolation |

| Contactor and precharge drivers | Controls HV contactors and precharge | Enables safe HV bus energization and shutdown |

| Connectors and harnessing | Interconnects cells, modules, and controller | Reliability and manufacturability inside harsh pack environment |

Interfaces to other vehicle systems

The BMS is tightly coupled to several systems in the EV.

- HV distribution (PDU/HVJB): contactor states, precharge status, HV safety isolation

- Charging (OBC/DC fast charging interface): charge limits, temperature limits, charge permission

- Thermal management (TMS): temperature targets and derating based on pack conditions

- Traction inverter and VCU (Vehicle Control Unit): available power, regen limits, fault states

- IVN (In-Vehicle Network): CAN/CAN-FD is common; Ethernet may appear via gateways in newer architectures

Safety role

The BMS is one of the most safety-critical controllers in an EV because it governs HV behavior and prevents pack operation outside safe limits.

- Fault detection: overvoltage, undervoltage, thermal faults, overcurrent, sensor plausibility

- Fault response: derating, contactor opening, safe-state signaling to the vehicle

- Crash response integration: coordinated HV shutdown pathways (implementation varies)

Battery supply chain relevance

From a supply chain viewpoint, the BMS is a pack-level electronics subsystem with significant semiconductor and validation content.

- AFEs (Analog Front Ends) and precision sensing drive BOM and qualification complexity

- MCU safety features and long lifecycle requirements are procurement-critical

- Module-level electronics scale with pack module count in distributed designs

HV/LV electrical relevance

From an HV/LV electrical viewpoint, the BMS is the controller that enforces HV safety and orchestrates pack connection to the vehicle HV bus.

- Controls contactors and precharge sequencing

- Interfaces with HV distribution and safety interlocks

- Reports limits to VCU and powertrain controllers

List of U.S.-based vendors of BMS:

| Manufacturer | State |

|---|---|

| AC Propulsion | CA |

| Akasol | MI |

| Analog Devices | MA |

| AVL LIST | |

| Battery Systems | |

| BorgWarner | MI |

| Boston-Power | MI |

| BYD | |

| Calsonic Kansei | |

| Cascadia Motion | OR |

| CATL | |

| Continental | |

| Denso | |

| Eberspacher | |

| Element Energy | CA |

| Elithion | |

| Ficosa | |

| G-Pulse | |

| Hella | |

| Hitachi | |

| Horiba Mira | |

| Indie Power Systems | TX |

| Infineon | CA |

| Intel | |

| Ion Energy | |

| Johnson Matthey | |

| Leclanche | |

| LG Electronics | NJ |

| Lithion Battery | NV |

| Lithion Battery | TX |

| Lithium Balance | |

| Lynntech | TX |

| Marelli | |

| Maxim | CA |

| Microvast | TX |

| Midtronics | |

| Mitsubishi | |

| Navitas System | |

| Nuvation Energy | ON |

| NXP Semiconductors | |

| Octillion Power | CA |

| Orient Technology | |

| Our Next Energy | MI |

| Panasonic Corporation | |

| Preh | |

| Renesas Electronics | |

| Ricardo | |

| Robert Bosch | |

| Roboteq | |

| Samsung SDI | |

| Silicon Labs | |

| ST Microelectronics | |

| SVolt | |

| TAE Power | CA |

| Tesla | |

| Texas Instruments | |

| Titan Advanced Energy | MA |

| Toshiba | |

| Turntide | CA |

| Vitesco | |

| Voltronix | CA |

| XALT Energy | MI |