Supply Chain > HV/LV Electrical > Thermal Management System

EV Thermal Management System

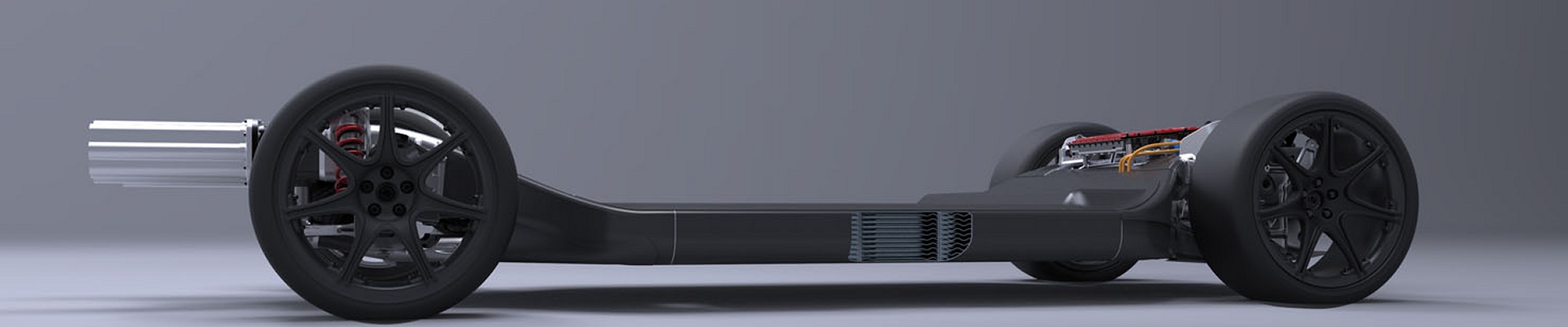

The Thermal Management System (TMS) is the vehicle hardware that controls temperatures of critical components and fluids, primarily the battery pack, power electronics, electric machines, and the cabin HVAC (Heating, Ventilation, and Air Conditioning) subsystem. In EVs, TMS is both a battery-supply-chain subsystem (pack-level thermal design and components) and a core HV/LV (High-Voltage / Low-Voltage) electrical subsystem because it contains high-power electrical loads and directly influences battery safety, performance, charging rate, and lifetime.

There are two ways the industry uses the term TMS:

- Battery TMS (BTMS, Battery Thermal Management System): the subset dedicated to battery pack heating/cooling and pack temperature uniformity

- Vehicle thermal system (sometimes referred to as a vehicle thermal system, integrated thermal system, or thermal management architecture): an integrated set of loops that may couple battery, power electronics/motor, and cabin HVAC via shared heat exchangers and valves

Many modern EVs implement an integrated thermal system where the battery loop is one part of a broader vehicle thermal architecture.

Why TMS matters in EVs

- Battery safety: avoids operation outside safe temperature ranges

- Battery performance: temperature affects available power and regen capability

- Fast charging: charging rate is often thermally limited; preconditioning improves charge time

- Battery lifetime: temperature uniformity reduces uneven aging

- Efficiency and range: heat pumps and integrated thermal architectures can reduce energy consumption

What TMS controls

- Battery pack temperature and temperature uniformity

- Power electronics temperature (inverter, DC-DC, OBC where liquid cooled)

- Motor and gearbox temperature (where liquid cooled)

- Cabin comfort (HVAC)

- Defrost/defog functions that affect visibility and sensor operation (architecture dependent)

Battery vs vehicle thermal management

This table clarifies the partition.

| Subsystem | Primary purpose | Main components | Interfaces | Typical naming |

|---|---|---|---|---|

| Battery thermal management | Keep battery within safe and optimal temperature range; enable fast charging | Coolant plates/paths, pumps, valves, chiller interface, heaters, sensors | Strong coupling to BMS; interacts with charging and VCU | BTMS, battery loop, pack thermal system |

| Vehicle thermal system (integrated) | Optimize overall vehicle heat flows and efficiency across battery, powertrain, and cabin | Heat pump or AC compressor, condensers, evaporators, radiators, chillers, valves, pumps, manifolds | Interfaces with BMS, VCU, HVAC controller, sometimes central compute | Integrated thermal system, vehicle TMS, thermal architecture |

Common EV thermal architectures

EVs typically use multiple fluid loops. The exact number and coupling strategy varies by OEM.

- Coolant loop(s): carry heat between components and radiators/chillers

- Refrigerant loop: used by AC compressor/heat pump for cabin conditioning and battery chilling via a chiller

- Coupling strategy: shared heat exchangers and valves can transfer heat between loops

Key TMS hardware

TMS BOM content includes both mechanical and electrical components.

| Component | Function | Battery relevance | HV/LV relevance |

|---|---|---|---|

| Coolant pumps | Circulate coolant through loops | Moves heat in/out of battery cooling plates | LV electrical loads; reliability-critical |

| Valves (solenoid and multi-way) | Direct coolant/refrigerant flow paths | Controls battery cooling/heating routing | LV actuation and control; enables integrated architectures |

| Heat exchangers (radiator, chiller, condenser, evaporator) | Transfer heat to/from air or between loops | Battery chilling via chiller interface in many designs | Defines cooling capacity and efficiency |

| AC compressor / heat pump | Moves heat via refrigerant cycle | Enables strong battery cooling and preconditioning | Often HV load; significant power draw at peak demand |

| Heaters (PTC heaters and/or other) | Adds heat for cabin and battery heating | Battery heating improves winter performance and fast charging | Often HV load; impacts range |

| Thermal interface hardware (cold plates, channels, TIM) | Moves heat from cells/electronics into coolant | Pack-level design driver for uniformity and safety | Mechanical integration within pack and power electronics |

| Sensors (temperature, pressure, flow) | Measure loop conditions | Enables safe pack control and derating | Feeds controllers for diagnostics and protection |

| Reservoirs, lines, quick-connects | Fluid containment and routing | Packaging and serviceability | Leak reliability and manufacturing quality drivers |

Thermal Control Unit (controller) and control partitioning

Thermal control logic can live in multiple places depending on OEM architecture.

- Dedicated Thermal Control Unit (sometimes called a thermal controller ECU): controls pumps/valves and coordinates loops

- BMS involvement: sets battery temperature targets, charging limits, and safety derating

- VCU involvement (Vehicle Control Unit): coordinates vehicle-level energy and operating modes

- Infotainment/HVAC controller involvement: cabin comfort control and user requests

Interfaces to other EV systems

- BMS (Battery Management System): battery temperature targets, safety limits, preconditioning requests

- Charging systems (OBC/DC fast charging): thermal limits often gate charging rate

- HV power electronics: inverter/DC-DC/OBC temperatures and cooling demand

- PDU/HVJB (Power Distribution Unit / High-Voltage Junction Box): power feeds for compressors and heaters

- IVN (In-Vehicle Network): CAN/CAN-FD common for thermal controllers; Ethernet appears in newer centralized designs

TMS as an HV/LV electrical subsystem

TMS includes multiple electrical loads and control paths that sit across HV and LV.

- HV loads (common): AC compressor, PTC heaters, some high-power pumps (varies)

- LV loads (common): valves, sensors, control electronics, many pumps and fans

- Design focus: ensure stable power delivery and fault handling for safety-critical cooling and heating functions

Battery supply chain relevance

From a battery supply chain perspective, thermal management is a pack-level performance and safety differentiator.

- Pack thermal design (plates/channels/contact) influences fast charge capability and cycle life

- Component sourcing impacts reliability and cold-weather performance

- Manufacturing quality drives leak rates, air entrapment risk, and long-term service outcomes

List of U.S.-based vendors for TMS:

| Manufacturer | State |

|---|---|

| 3M | AL |

| 3M | MN |

| ADA Technologies | CO |

| Borgwarner | |

| Calogy Solutions | QC |

| Calsonic Kansei | |

| CapTherm Systems | |

| Continental | |

| Dana | |

| Gentherm | |

| Hanon System | |

| HotStart Thermal Management | WA |

| HYLIION | TX |

| KULR Technology | CA |

| Latent Heat Solutions | OH |

| Latent Heat Solutions | CO |

| LG Energy | |

| MAHLE | |

| Morgan Advanced Materials | IL |

| Morgan Advanced Materials | GA |

| Morgan Advanced Materials | KS |

| Morgan Advanced Materials | IN |

| Nanoramic Laboratories | MA |

| Parker LORD | IN |

| Robert Bosch | |

| Samsung SDI | |

| Senior Flexonics | IL |

| Senior Flexonics | Coahuila |

| SGL Carbon | CA |

| SGL Carbon | NC |

| SGL Carbon | PA |

| SGL Carbon | PA |

| Valeo | |

| VOSS Automotive |