Supply Chain > HV/LV Electrical > Power Distribution Units

EV Power Distribution Unit

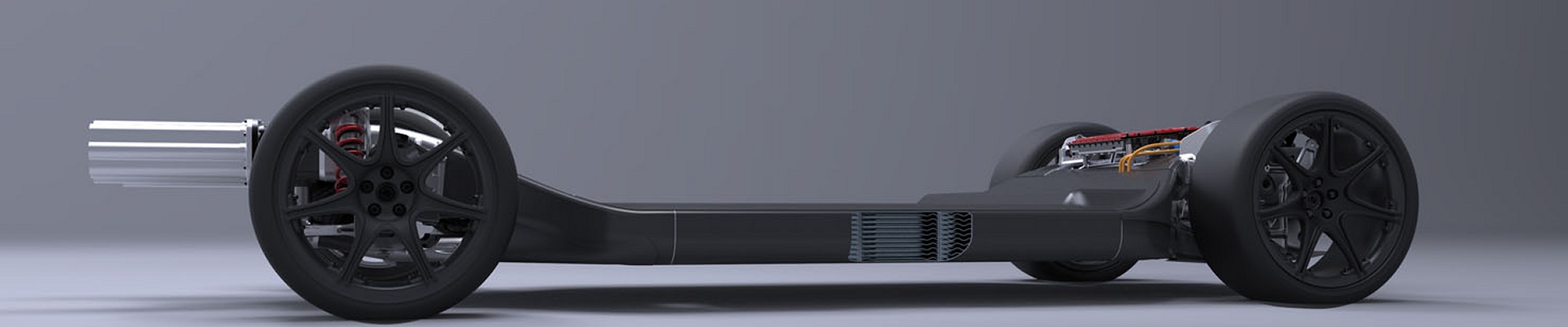

A Power Distribution Unit (PDU) is the vehicle hardware that safely routes electrical power from the source (battery and low-voltage bus) to loads across the vehicle. In EVs (Battery Electric Vehicles), PDUs commonly include HV (High-Voltage) junction boxes and LV (Low-Voltage) distribution modules, integrating protection, switching, diagnostics, and in some designs, smart load management.

Why PDUs matter in EV architectures

EVs concentrate large electrical power flows and add high-power electronics loads. PDUs enforce safety, isolation, and fault containment while supporting increasingly dynamic loads such as fast-changing compute power draw from ADAS/AV inference platforms.

HV vs LV distribution

Most EVs have at least two distinct electrical domains.

- HV domain: traction battery voltage (commonly hundreds of volts) feeding inverters, OBC (On-board Charger), heaters, compressors, and DC-DC

- LV domain: 12 V and/or 48 V feeding controllers, lights, infotainment, and compute platforms

| Distribution domain | Typical sources | Typical loads | Primary PDU objectives |

|---|---|---|---|

| HV distribution | Traction battery, HV bus | Traction inverter, OBC, HV heaters, HVAC compressor, DC-DC | Isolation, safe switching, fault protection, serviceability |

| LV distribution | 12 V and/or 48 V rails (from DC-DC) | ECUs, lighting, pumps, infotainment, ADAS inference compute | Load protection, diagnostics, power management, sleep/wake behavior |

PDU hardware

PDU content varies by OEM, but the following blocks are common in EVs.

| Hardware block | What it does | Why it matters |

|---|---|---|

| HV contactors | Connect/disconnect traction battery to HV bus | Primary safety switching element for HV isolation |

| Precharge circuit | Limits inrush current when energizing HV bus capacitors | Protects components and improves reliability during HV wake-up |

| Fuses and fuse links | Overcurrent protection on HV and LV branches | Defines fault boundaries and prevents cascading failures |

| Pyro-fuse (pyrotechnic disconnect) | Rapid HV disconnection in severe fault events | Crash and fault safety; enables fast isolation beyond mechanical contactors |

| Current and voltage sensing | Measures branch and bus conditions | Enables diagnostics, power limiting, and fault detection |

| Isolation monitoring (where used) | Detects leakage to chassis ground | Critical safety mechanism for HV systems |

| Smart switching (MOSFET/solid-state) (where used) | Electronic load switching with diagnostics | Supports software-defined power management and faster fault isolation |

| Control electronics (MCU and drivers) | Controls switching and monitors PDU health | Enables diagnostics, safety logic, and vehicle integration |

Smart PDU vs conventional PDU

Some OEMs are moving from passive fuse boxes to “smart” PDUs that provide per-load switching, current measurement, and fault reporting.

| PDU type | Primary switching | Diagnostics | Typical benefits |

|---|---|---|---|

| Conventional PDU | Contactors + fuses | Limited (branch-level) | Lower cost, mature supply chain |

| Smart PDU | Solid-state switches and/or electronically controlled relays | Richer (per-load measurement and reporting) | Better fault isolation, software-defined power control, improved serviceability |

How PDUs interface with major loads

PDUs are not power converters, but they gate and protect the power paths that feed converters and high-power loads.

- Traction inverter: HV feed via PDU branch protection and contactor logic

- OBC (On-board Charger): HV feed and charging safety isolation paths

- DC-DC converter: HV input branch and LV rail distribution downstream

- Thermal loads: HV heaters, compressors, pumps, fans (HV and LV mix)

ADAS/AV compute as a PDU load

The ADAS/AV inference computer/platform is a major LV electrical load in advanced vehicles. It can behave differently than traditional ECUs due to higher sustained power draw and fast dynamic transients, which influence LV distribution design.

- Power domain: LV (12 V or 48 V) fed from the DC-DC converter

- Implications for PDU design: stable rails, transient handling, brown-out avoidance, and diagnostic visibility

- Operational modes: sleep/wake cycles and always-on behavior can require dedicated PDU power channels

| Compute load characteristic | What it means electrically | PDU / LV distribution implication |

|---|---|---|

| High sustained draw | Compute draws materially more power than typical ECUs | Dedicated fused branch, heavier gauge wiring, improved thermal design |

| Fast transients | Rapid load changes during inference bursts | Power rail stability, decoupling, transient response requirements for LV distribution |

| Always-on / standby modes | Vehicle may keep connectivity or monitoring alive | PDU channel control strategy for sleep/wake and low quiescent loss |

| Safety relevance | Compute availability can be tied to ADAS functions | Prioritized power paths and monitoring to avoid unexpected resets |

Safety boundaries and fault containment

PDUs define electrical fault boundaries and enable safe isolation.

- Short-circuit containment: fuses and branch protection prevent cascading failures

- Crash isolation: pyro-fuse or fast disconnect logic isolates HV

- Service safety: HV interlock loops and controlled discharge strategies (architecture dependent)

- Diagnostics: sensing and reporting enable predictive maintenance and faster troubleshooting

Voltage domain

PDUs span both domains.

- HV PDU: handles traction-battery distribution and HV safety switching

- LV PDU: distributes 12 V and/or 48 V to loads (often with smart switching in newer designs)

Supply-chain notes

PDU supply chain includes high-reliability electromechanical and protection components plus increasing semiconductor content for smart PDUs.

- Contactors and relays: high-voltage, high-cycle reliability constraints

- Protection: fuses, pyro-fuses, current sensors, isolation monitors

- Power switches: MOSFETs and gate drivers for smart load control (where used)

- Enclosures and connectors: thermal, sealing, and serviceability constraints

- Manufacturing: harness integration and HV safety validation are critical