Systems Hub > EV Platforms > BYD EV platforms

BYD EV Platform Families

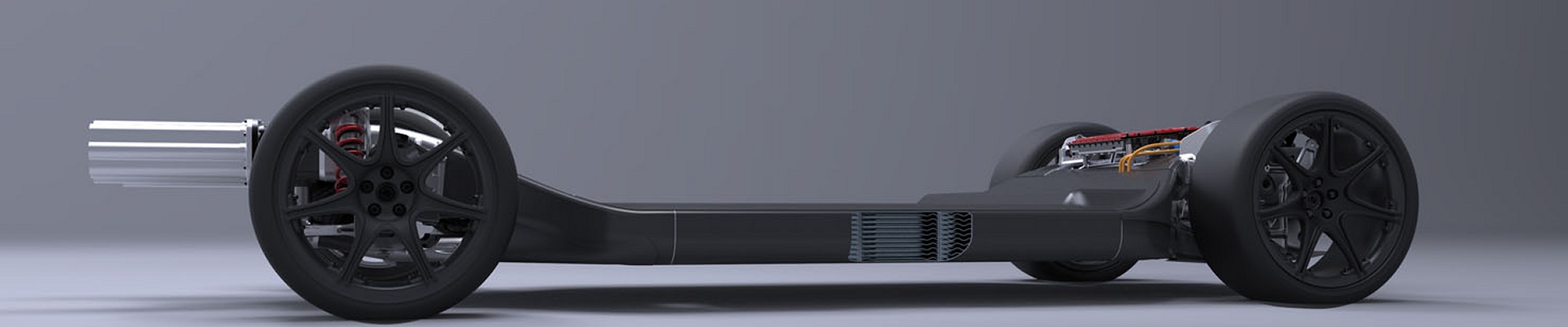

This article summarizes BYD’s major EV platform families and how they map to the company’s multi-brand portfolio. A platform is not just a chassis. It is a layered system that shapes real-world behavior: charging curve stability, sustained performance, thermal limits, software longevity, and autonomy headroom.

BYD operates multiple brands with different platform needs. Some platforms are broad and high-volume (BYD passenger EVs). Others are purpose-built for extremes (four-motor performance, off-road duty cycles, or premium control architectures).

- BYD (core): high-volume passenger EV platforms (e-Platform family)

- Yangwang: performance and extreme maneuvering architecture (e4)

- Denza: premium control-focused architecture (e3)

- Fangchengbao: off-road oriented platform family (DMO)

What an EV platform controls

A modern EV platform is best understood as four tightly coupled layers. These layers determine how the vehicle behaves more than most isolated specs.

- Structural and energy layer: battery-to-body integration (CTB), crash structure, suspension hard points

- Electrical and compute architecture: controller consolidation, in-vehicle networking, compute topology

- Thermal and power management: battery and drive-unit cooling, heat pump integration, power limits

- Software and OTA capability: telemetry scope, OTA depth, ADAS and autonomy integration

BYD platform lineup

| Platform / Architecture | Brand Scope | Primary Use | Voltage / Charging Direction | Signature Traits |

|---|---|---|---|---|

| e-Platform 3.0 | BYD (core) | Dedicated BEV passenger platform family | BEV-optimized; fast-charge focus (program dependent) | BEV-first integration; CTB (cell-to-body) emphasis; integrated e-powertrain packaging |

| e-Platform 3.0 Evo | BYD (core) | Upgraded BEV platform (e-Platform 3.0 evolution) | Higher integration; stronger charging and powertrain performance (program dependent) | Refined CTB integration and system efficiency improvements |

| Super e-Platform | BYD (core) | Ultra-fast charging BEV platform (next step) | 1000 V-class architecture; ultra-high peak charge power (program dependent) | Designed to enable very high charging rates; requires matching high-power charging infrastructure |

| e4 Platform | Yangwang | Quad-motor independent-drive performance architecture | High-voltage performance-focused (program dependent) | Four independent motors; extreme maneuvers (tank turn); torque vectoring as a platform primitive |

| e3 Platform | Denza | Premium control and intelligence architecture | Program dependent (BEV and some multi-powertrain variants exist) | Control-centric chassis integration; multi-motor coordination; premium dynamics focus |

| DMO Platform | Fangchengbao | Off-road platform family (range-extending / hybrid-oriented) | Not BEV-only; off-road duty-cycle-first | Off-road energy management; platform-level torque coordination; ruggedized packaging assumptions |

e-Platform 3.0 and e-Platform 3.0 Evo

The e-Platform 3.0 family is BYD’s dedicated BEV architecture for mainstream passenger vehicles. The Evo update is positioned as a higher-integration evolution with stronger charging and powertrain performance, while retaining BEV-first platform principles.

What e-Platform 3.0 family platforms tend to enable:

- Battery-to-body integration strategies (CTB) that improve stiffness and packaging efficiency

- Higher system integration of e-powertrain building blocks

- Consistent platform behavior across many models as software and thermal strategies mature

Super e-Platform (1000 V-class)

BYD has described a 1000 V-class platform direction intended to support very high charging power. Platform capability and real-world charging outcomes depend on charger availability, thermal control strategy, and the battery’s allowable charge window under temperature constraints.

Why 1000 V-class matters:

- Lower current for a given charging power reduces cable and thermal stress

- Potentially enables higher peak charging rates if the battery and thermal systems support it

- Pairs naturally with high-power corridor charging infrastructure

Yangwang e4 platform

The e4 platform is a quad-motor independent-drive architecture used by BYD’s Yangwang brand. It treats torque vectoring and independent wheel control as a first-order platform capability, enabling extreme maneuvers and stability control behaviors.

What quad-motor platforms tend to enable:

- Independent torque control at each wheel (fine-grain torque vectoring)

- Extreme maneuvering modes (example: tank turn) where permitted and safe

- High stability margins under high-power launches and dynamic cornering

Denza e3 platform

The e3 platform is positioned as a premium, control-centric architecture for Denza. The defining idea is tight integration of drive, chassis control, and platform coordination to deliver premium dynamics and control behaviors.

Fangchengbao DMO platform

DMO is an off-road oriented platform family introduced under Fangchengbao. It is commonly described as a super-hybrid off-road platform, prioritizing off-road energy management, torque coordination, and rugged packaging assumptions.

Note: If your vehicle database is BEV-only, the DMO platform can still be referenced as an “architecture neighbor” for off-road duty-cycle design patterns, but should be clearly labeled as not BEV-only.