Systems Hub > EV Platforms > GM EV platforms

General Motors EV Platforms

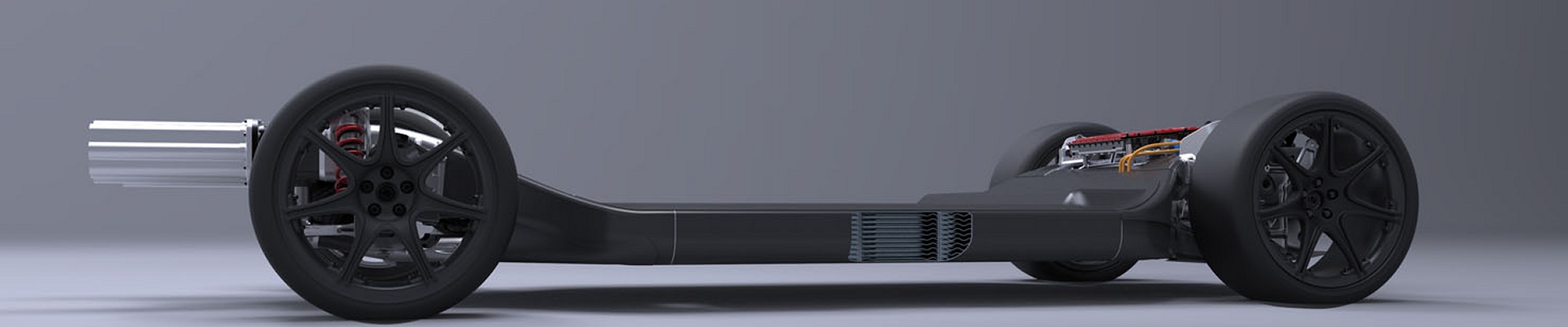

This article summarizes General Motors' major EV platform families and why they matter. A platform is not just a chassis. It is a layered system that shapes real-world behavior: charging curve stability, sustained performance, thermal limits, software longevity, and autonomy headroom.

GM platforms are shared across brands (for example: Chevrolet, GMC, Cadillac). Brand execution differentiates styling, performance tuning, option packaging, and software features, while the platform determines the deep constraints and capabilities (charging behavior, thermal headroom, EEA capacity).

What a GM platform controls

GM's platform strategy is best understood as an EV hardware platform family plus a software-defined vehicle (SDV) layer that evolves OTA scope, diagnostics, and feature velocity.

- Structural and energy layer: pack layout, crash structure, suspension hard points, modular body packaging

- High-voltage and charging layer: voltage class, fast-charge headroom, thermal management integration

- EEA (electrical/electronic architecture): controller consolidation, in-vehicle networking, service diagnostics

- Software + OTA capability: platform-level software direction that determines what can be updated and how often

GM platform roadmap

GM's EV platform roadmap can be summarized as:

- Ultium platform family: modular battery + drive components used across multiple GM brands

- BT1-based large EV architecture: full-size trucks and large SUVs (high-duty, high-mass, towing capable)

- SDV direction: deeper software integration and broader OTA scope across future generations

GM EV platform lineup

| Platform / Architecture | Primary Use | Voltage / Charging | Architecture Direction | Representative Examples |

|---|---|---|---|---|

| Ultium (platform family) | Broad passenger + commercial EV portfolio across GM brands | Vehicle dependent (400 V common; higher-voltage designs exist on select programs) | Modular pack + drive components intended to scale across segments | Chevrolet Blazer EV, Equinox EV; Cadillac LYRIQ; GMC Hummer EV (Ultium-based programs) |

| BT1 (full-size EV architecture) | Full-size trucks and large SUVs (heavy, towing-oriented) | Vehicle dependent; designed for high pack energy and high peak power | Truck/SUV architecture emphasizing durability, payload/towing, and large-pack thermal capacity | Chevrolet Silverado EV; GMC Sierra EV; Cadillac Escalade IQ (program family examples) |

| Commercial / fleet variants (Ultium programs) | Work-focused EVs (vans, pickups, service/fleet) | Vehicle dependent; focuses on uptime, charging workflow, service access | Fleet-driven packaging and durability tuning atop core platform modules | BrightDrop (GM commercial EV programs); work-truck trims across brands |

Ultium (platform family)

Ultium is GM's modular EV platform family concept: shared battery and drive building blocks across many brands and segments. The key platform question is not the badge, but how consistently the underlying architecture delivers predictable charging, thermal behavior, and software upgrade headroom.

What Ultium tends to enable:

- Broad reuse across multiple segments and brands

- Shared module strategy that can lower cost and accelerate rollout

- Platform-level evolution over time without redesigning every vehicle from scratch

See the Ultium platform page.

BT1 (full-size truck/SUV architecture)

BT1 is associated with GM's full-size EV truck and large SUV architecture. These vehicles stress platforms differently: high mass, towing loads, sustained thermal demand, and large energy throughput. That makes charge-curve stability, thermal sizing, and power electronics limits first-order platform behaviors.

What BT1-style architectures tend to enable:

- Large-pack packaging with heavy-duty thermal design

- High peak power capability and towing-oriented chassis hardpoints

- Fleet and work-truck configurations that prioritize durability and serviceability

See the GM full-size EV architecture page.