Systems hub > EV Platforms > Hyundai EV platforms

Hyundai Motor EV Platforms

This article discusses the Hyundai Motor Group major EV platforms and why they matter. A platform is not just a chassis. It is a layered system that shapes real-world behavior: charging curve stability, sustained performance, thermal limits, software longevity, and autonomy headroom.

What an EV platform controls

A modern electric vehicle platform is best understood as four tightly coupled layers. These layers determine how the vehicle behaves more than most isolated specs.

- Structural and energy layer: pack layout, crash structure, suspension hard points

- Electrical and compute architecture: centralized vs zonal design, in-vehicle networking, controller consolidation

- Thermal and power management: battery cooling, drive unit and inverter cooling, heat pump integration

- Software and OTA capability: vehicle OS direction, telemetry, OTA scope, ADAS and autonomy integration

Hyundai EV platform roadmap

Hyundai Motor Group’s EV platform roadmap can be summarized as:

- E-GMP: current dedicated passenger EV platform family

- IMA: next-generation architecture intended to replace E-GMP over time

- PBV platforms: dedicated flat “skateboard” bases for purpose-built commercial vehicles

Platforms are shared across Hyundai, Kia, Genesis brands.

Hyundai EV platform lineup

| Platform | Primary Use | Voltage / Charging | Architecture Direction | Representative Examples |

|---|---|---|---|---|

| E-GMP | Passenger EVs (Hyundai, Kia, Genesis) | 800 V-class fast charging with 400 V compatibility | Gen-1 dedicated EV platform; designed to scale across body types | IONIQ 5, IONIQ 6, EV6, GV60 |

| IMA | Next-gen passenger EVs and SDV-aligned vehicles | TBD (public specs vary by future vehicle) | SDV-first direction; higher modularization and standardization | Future Hyundai, Kia, Genesis EV generations |

| E-GMP.S | PBV skateboard concept applied to E-GMP family | TBD (program dependent) | Flat skateboard base to accept multiple upper bodies | PBV concepts and early PBV program vehicles |

| eS | Dedicated BEV PBV skateboard platform (commercial) | TBD (program dependent) | Purpose-built skateboard enabling modular bodies | Kia PBV program (PV-series) and related PBVs |

E-GMP (Electric-Global Modular Platform)

E-GMP is Hyundai Motor Group’s first dedicated passenger-EV platform family. It was designed for high fast-charging performance and for scaling across multiple vehicle segments.

What E-GMP tends to enable:

- Strong DC fast-charging capability (800 V-class charging behavior)

- Compatibility with mainstream 400 V DC fast chargers

- Flexible motor layouts (RWD and AWD variants)

- Flat-floor packaging and efficient cabin utilization

See the E-GMP platform.

IMA (Integrated Modular Architecture)

IMA is the next-generation platform architecture intended to replace E-GMP over time. The stated goal is deeper component modularization (batteries, motors, and common architecture elements) and a more software-defined vehicle (SDV) direction.

What IMA is expected to focus on:

- Higher standardization of core EV modules across many models

- Electrical architecture evolution toward SDV patterns (higher compute centralization, more consolidation)

- Improved lifecycle upgrade path through OTA and platform-level software capabilities

See the IMA platform.

PBV Platforms: E-GMP.S and eS

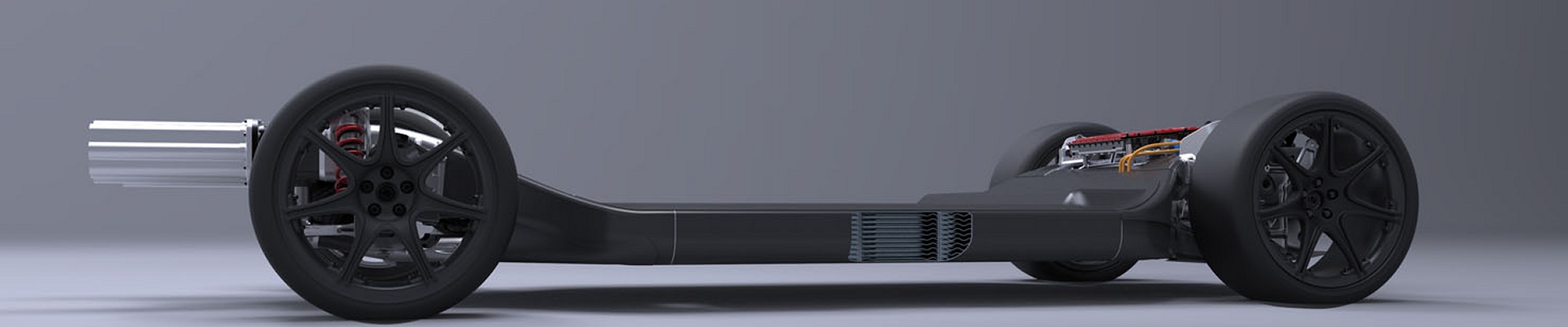

PBVs (Purpose-Built Vehicles) are commercial-first vehicles designed around a mission (delivery, service, shuttle, logistics). They prioritize modular bodies, rapid upfitting, and lifecycle fleet operations.

Why PBV platforms are different:

- Skateboard base supports multiple upper bodies without re-engineering the entire vehicle

- Designed around fleet uptime, serviceability, and configurable interiors

- More “system” thinking: vehicle + software + charging + operations

Hyundai Motor Group has discussed applying a skateboard concept as E-GMP.S, and Kia has described a dedicated PBV skateboard platform called eS for its PBV lineup.

See the PBV platform.