Systems Hub > EV Platforms > Mercedes-Benz EV platforms

Mercedes-Benz EV Platforms

This article summarizes the Mercedes-Benz Group’s major EV platforms and why they matter. A platform is not just a chassis. It is a layered system that shapes real-world behavior: charging curve stability, sustained performance, thermal limits, software longevity, and autonomy headroom.

Mercedes-Benz Group uses a platform strategy where the same underlying architecture can support multiple brand executions. In practice: Mercedes-Benz is the core brand, Mercedes-AMG is the performance execution, Mercedes-Maybach is the ultra-luxury execution, and Mercedes-Benz Vans covers commercial vans. The “execution” can change tuning, interiors, body programs, and software packaging, while still sharing a core platform family.

What an EV platform controls

A modern EV platform is best understood as four tightly coupled layers. These layers determine how the vehicle behaves more than most isolated specs.

- Structural and energy layer: pack layout, crash structure, suspension hard points

- Electrical and compute architecture: centralized vs zonal design, in-vehicle networking, controller consolidation

- Thermal and power management: battery cooling, drive unit and inverter cooling, heat pump integration

- Software and OTA capability: vehicle OS direction, telemetry, OTA scope, ADAS and autonomy integration

Mercedes-Benz EV platform roadmap

The platform roadmap can be summarized as:

- Legacy / current: MFA2 (compact), EVA2 (EQE/EQS generation)

- Next-gen “electric-first”: MMA (new CLA-class family and compact/core segment)

- Next-gen scalable: MB.EA (next electric architecture for core/top-end segments)

- Performance: AMG.EA (dedicated high-performance architecture)

- Vans: VAN.EA (dedicated electric van architecture)

Mercedes-Benz EV platform lineup

| Platform | Primary Use | Voltage / Charging | Architecture Direction | Representative Examples |

|---|---|---|---|---|

| MFA2 | Compact vehicles (legacy multi-powertrain base used for early EQ compacts) | Typically 400 V-class (model dependent) | Legacy architecture; not SDV-first; being phased out over time | EQA, EQB (generation dependent) |

| EVA2 | Large EVs (current EQ flagship generation) | 400 V-class today; future updates may evolve (program dependent) | Dedicated EV platform for EQE/EQS era; being iterated while next-gen ramps | EQS, EQE (sedan and SUV) |

| MMA | Entry / core segment (new compact-to-mid EV programs) | 800 V-class capability emphasized on new programs | “Electric-first” modular architecture; supports a modern compute + OTA direction | New CLA-class EV family |

| MB.EA | Next-gen BEV architecture for core and top-end segments | TBD (program dependent) | Next electric architecture aligned to SDV direction (MB.OS) and scalable modularization | Future EV generations above MMA |

| AMG.EA | Dedicated high-performance BEVs | TBD (program dependent) | Performance-first architecture; AMG-specific powertrain + dynamics targets | Future AMG EVs on AMG.EA |

| VAN.EA | Dedicated electric vans (commercial and private vans) | TBD (program dependent) | Purpose-built BEV van architecture; modular/scalable; “starting 2026” for newly developed vans | Next-gen electric vans; future private and commercial van programs |

MMA (Mercedes Modular Architecture)

MMA is the modern “electric-first” modular platform intended to anchor the next generation of compact and core-segment vehicles. It is designed to carry a more advanced electrical architecture and a longer software lifecycle than older shared platforms.

What MMA tends to enable:

- High fast-charging potential on new programs (often positioned as 800 V-class)

- Modernized compute + OTA posture for longer feature lifecycle

- Better packaging efficiency versus legacy multi-powertrain compromises

See the MMA platform.

MB.EA (next electric architecture)

MB.EA is described by Mercedes-Benz as the next electric architecture for next-generation BEVs, aligned to a software-defined direction (MB.OS) and scalable modularization. The intent is to reuse high-end technologies efficiently across multiple vehicle programs.

What MB.EA is expected to focus on:

- Scalable modular building blocks across multiple vehicle sizes

- Deeper integration of software architecture (functional zones, OTA, data/telemetry)

- Clear separation of “platform” capability from “brand execution” tuning

See the MB.EA platform.

AMG.EA (performance architecture)

AMG.EA is the dedicated high-performance architecture intended for AMG’s next BEV generation. The goal is not simply more power; it is repeatable performance, thermal robustness, and dynamics control that holds up under aggressive duty cycles.

How AMG.EA is typically positioned:

- Performance-first system targets (power density, torque response, heat rejection)

- Chassis + software integration for dynamics and stability at speed

- Distinct brand execution versus the same vehicle line on a non-AMG platform

See the AMG.EA platform.

VAN.EA (van electric architecture)

VAN.EA is the dedicated BEV platform for newly developed Mercedes-Benz vans, positioned as a single modular and scalable architecture. Vans have unique packaging goals (load floor, cargo volume, service access), so this platform is engineered around van-first requirements rather than adapted from passenger-car architectures.

Why van platforms are different:

- Prioritize flat load floor, payload efficiency, and cargo packaging

- Designed around fleet uptime, serviceability, and long lifecycle duty cycles

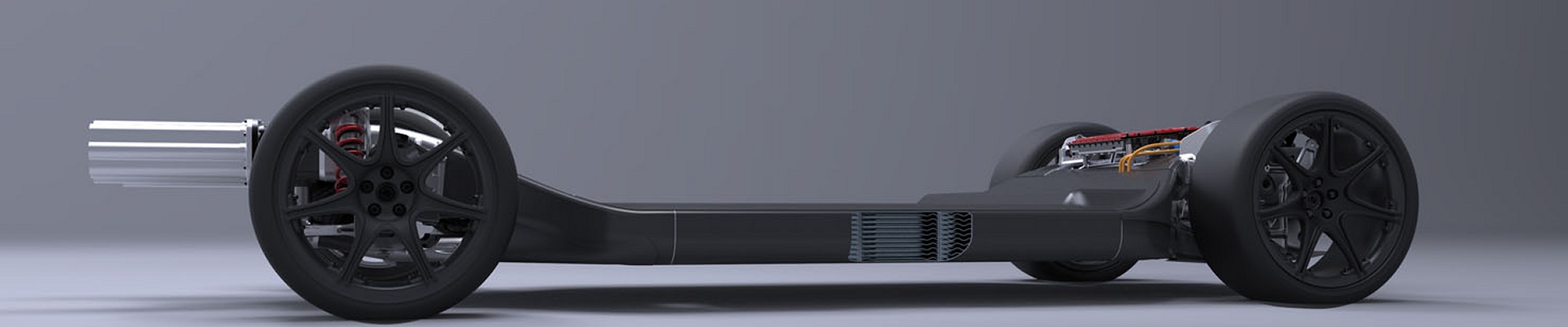

- Enable multiple body programs from a common skateboard-style base

See the VAN.EA platform.