Systems Hub > EV Platforms > NIO EV platforms

NIO EV Platforms

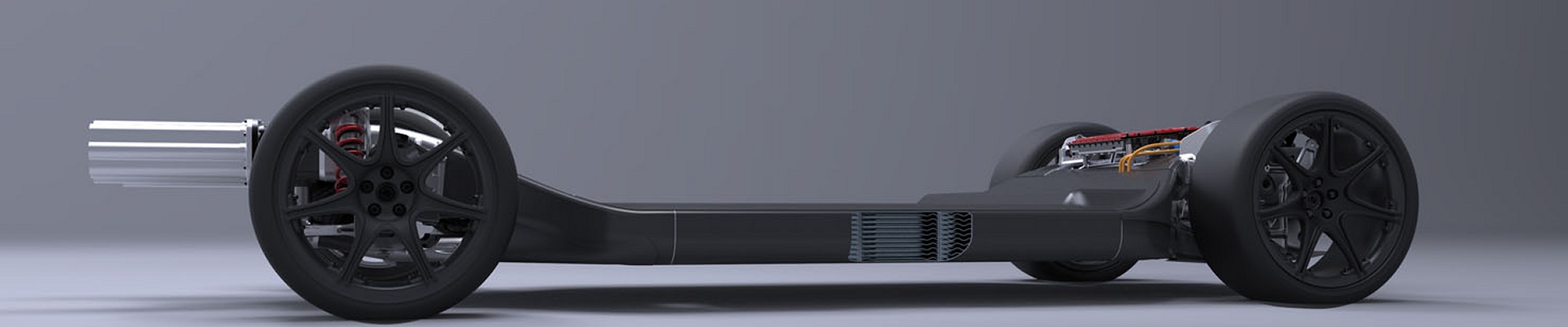

This article summarizes NIO's major EV platform generations and why they matter. A platform is not just a chassis. It is a layered system that shapes real-world behavior: charging curve stability, sustained performance, thermal limits, software longevity, and autonomy headroom.

What a NIO platform controls

NIO platform generations are best understood as four coupled layers that move together across model families.

- Structural and energy layer: pack layout, crash structure, suspension hard points, underbody integration

- High-voltage layer: voltage class (400 V vs 800/900 V), peak charge power capability, power electronics strategy

- Electrical/electronic architecture (EEA): compute topology, controller consolidation, in-vehicle networking, OTA scope

- Autonomy and sensing layer: sensor suite integration, compute headroom, safety and redundancy direction

NIO platform roadmap

NIO's platform roadmap is commonly described as NT generations, plus a separate fleet-scale layer: battery swap / BaaS.

- NT2: current generation used across multiple NIO model families

- NT3: next generation direction (higher-voltage architecture appears on flagship programs)

- Battery swap / BaaS: an infrastructure + pack-interface layer that changes lifecycle economics and refueling behavior

NIO platform lineup

| Platform / Architecture | Primary Use | Voltage / Charging | Architecture Direction | Representative Examples |

|---|---|---|---|---|

| NT2 | Core NIO passenger EV generation | Vehicle dependent; supports fast-charge and swap-enabled programs | Gen-2 platform generation enabling newer sensing/compute and broader OTA scope | ET7, ET5, EL7/ES7 (NT2 is publicly referenced for these programs) |

| NT3 | Next-gen platform generation (NIO + sub-brands) | Flagship programs reference 900 V-class architecture | Higher-voltage system direction; continued SDV alignment via deeper EEA integration | ET9 (900 V architecture messaging); ONVO L60 is described as an NT3 platform model |

| Battery swap / BaaS | Energy interface + operations layer (infrastructure + vehicle pack interface) | Swap in minutes; charging handled off-vehicle inside stations | Decouples vehicle purchase from pack ownership options; changes "refuel" pattern vs plug-in only | NIO swap-enabled model families; ONVO messaging indicates shared access to swap network |

| EEA + compute (Adam / Orin-era) | Vehicle compute layer for SDV and ADAS | Enables broader OTA and sensor/compute integration | Central compute concept paired with domain functions; supports ADAS evolution | NIO Europe messaging highlights NT2 models built on Adam; ONVO L60 uses NVIDIA DRIVE Orin |

NT2 (current generation)

NT2 is the current-generation platform widely referenced across NIO's modern passenger EV lineup. Practically, NT2 matters because it anchors the vehicle-level integration of sensing/compute, electrical architecture capability, and the platform behavior that buyers experience over years of updates.

What NT2 tends to enable:

- More integrated ADAS sensor and compute packaging vs older generations

- Broader OTA reach (more vehicle functions updateable over time)

- Consistent platform behavior across multiple model families (charging, thermal behavior, software features)

See the NT2 platform.

NT3 (next generation)

NT3 is the next-generation platform direction. Public flagship messaging emphasizes a full-domain 900 V high-voltage architecture on ET9, and ONVO's first model is described as an NT3 platform vehicle. In platform terms, this points to a higher-voltage system baseline, which can improve high-power charging headroom and reduce current for a given power level.

What NT3 is expected to focus on:

- Higher-voltage architecture baseline on next-gen programs (900 V-class appears in public flagship specs)

- Continued SDV alignment through stronger EEA integration and platform modularization

- Compute and sensor integration designed for longer lifecycle upgrades

See the NT3 platform.

Battery swap / BaaS (platform-scale energy layer)

Battery swap changes the platform story because it adds an external energy layer: the vehicle is designed around a pack interface, and the station becomes part of the energy system. For operators, swap can act like “refueling” in minutes while charging happens off-vehicle inside stations, which can be valuable for high utilization patterns.

Why swap is a platform topic (not just infrastructure):

- Vehicle design must support pack interface, mechanical alignment, and pack compatibility rules

- Pack strategy becomes a lifecycle option (ownership vs subscription models)

- It reshapes duty-cycle planning for fleets and time-sensitive consumer use cases

See the Battery swap and BaaS.