Systems Hub > EV Platforms > Tesla EV platforms

Tesla EV Platforms

This article summarizes Tesla’s EV platforms. The platform is not just a chassis. It is a layered system that shapes real-world behavior: charging curve stability, sustained performance, thermal limits, software longevity, and autonomy headroom.

What an EV platform controls

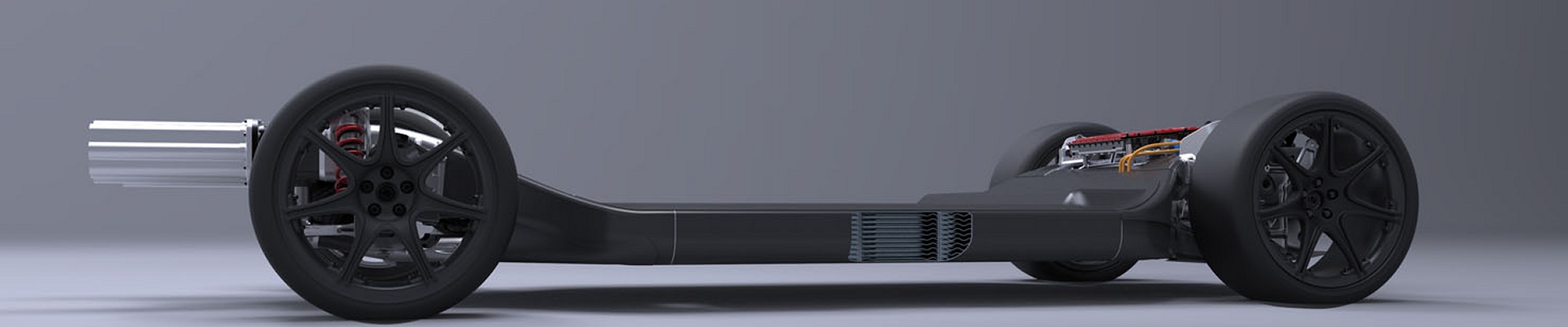

A modern EV platform is best understood as four tightly coupled layers. These layers determine how the vehicle behaves more than most isolated specs.

- Structural and energy layer: pack layout, crash structure, suspension hard points

- Electrical and compute architecture: centralized vs zonal design, in-vehicle networking, controller consolidation

- Thermal and power management: battery cooling, drive unit and inverter cooling, heat pump integration

- Software and OTA capability: vehicle OS direction, telemetry, OTA scope, ADAS and autonomy integration

Tesla platform taxonomy

Tesla platforms map cleanly into five platform families. Two are core passenger architectures (Gen2 and Gen3). The other three exist because they have different constraints: a transitional technology bridge (Cybertruck), a heavy commercial platform (Semi), and a purpose-built autonomy platform (Cybercab).

Tesla platform lineup

| Platform / Architecture | Primary Use | Defining Traits | Models / Programs | Status |

|---|---|---|---|---|

| Generation 2 (Gen2) | Current mass-production passenger EV architecture | Mature charging/thermal behavior; centralized compute; OTA-first lifecycle | Model S, Model X, Model 3, Model Y | In production |

| Generation 3 (Gen3) | Next-generation high-volume passenger EV architecture | Cost-down and manufacturability reset; modularization; SDV-first direction | Next-gen compact / future high-volume vehicles | Program dependent |

| Cybertruck transitional architecture | Technology bridge platform for new architecture elements | 48 V low-voltage shift; steer-by-wire; electrical simplification themes | Cybertruck | In production |

| Semi commercial platform | Heavy-duty commercial EV platform | Sustained power and thermal robustness; depot-first charging workflows; uptime focus | Semi | In production (ramp dependent) |

| Cybercab / Robotaxi platform | Purpose-built autonomy vehicle platform | Autonomy-duty-cycle-first packaging; interior-first; serviceability and utilization optimized | Cybercab / robotaxi program | Program dependent |

Generation 2 platform (Gen2)

Gen2 is Tesla’s current mass-production passenger EV architecture. It is best viewed as a stable foundation that has evolved through continuous engineering updates. The distinguishing behavior users feel is driven by platform-level thermal strategy, power electronics, battery control software, and OTA-driven feature evolution.

What Gen2 tends to enable:

- Consistent charging experience shaped by battery thermal strategy and charge-limits logic

- Strong efficiency from powertrain + thermal integration

- Software durability via frequent OTA updates and shared fleet-scale learnings

Generation 3 platform (Gen3)

Gen3 is Tesla’s next clean-sheet architecture intended to reset cost, manufacturability, and scaling. Public details vary by program, but the core idea is a deeper modularization of vehicle building blocks and a more standardized SDV direction.

What Gen3 is expected to focus on:

- Major cost reduction through platform simplification and manufacturing redesign

- Higher modularity for batteries, e-drive units, and standardized architecture elements

- Longer software feature lifecycle enabled by more consistent platform baselines

Cybertruck transitional architecture

Cybertruck is not Gen3, but it introduces architecture elements that act as a bridge between generations. The most visible example is the move toward a 48 V low-voltage subsystem, which supports wiring reduction and controller consolidation patterns.

Why transitional platforms matter:

- They de-risk new electrical architecture patterns ahead of full platform resets

- They validate new low-voltage and control strategies under real-world usage

- They can accelerate controller consolidation and serviceability improvements

Semi commercial platform

Heavy-duty EV platforms differ from passenger platforms because the duty cycle is dominated by sustained load, thermal constraints, and depot logistics. The right question is not peak acceleration; it is repeatable energy throughput, thermal robustness, and uptime planning.

What commercial platforms tend to prioritize:

- Thermal robustness under sustained power demand

- Depot-first charging and operations workflows

- Serviceability and uptime as first-order design constraints

Cybercab / Robotaxi platform

A purpose-built robotaxi is best treated as its own platform family. The platform is shaped around utilization, serviceability, interior layout, sensor/compute packaging, and autonomy duty-cycle constraints. Even if it borrows components from other platforms, the system priorities are different.

What robotaxi platforms tend to prioritize:

- High utilization and fast turnaround service workflows

- Interior-first design (passenger experience and durability)

- Compute and sensor packaging as primary system constraints